Customised appliance control

ROS Service: Benefit by the expertise of experienced engineers for your project

ROS supports you and your project “step by step” from the problem to testing and certification up to the productive application. We only use reliable hardware that will be available for many years. This ensures that your industrial application will work trouble-free for a long time.

ROS developes prototypes and productive devices for industrial solutions by integrating the innovative controllers of the Smartstep-Family. These prototypes can excellently be used for testing and developing in combination with our software solution PSC (Personal Stepper Controller). The included DLLs can be integrated into your own software applications.

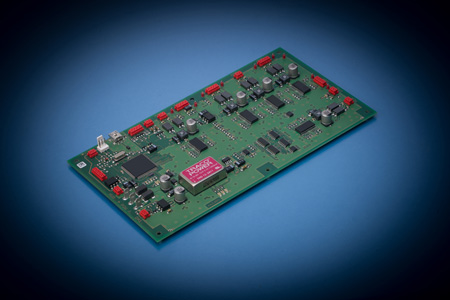

Example: Complete device electronics on a printed circuit board. Power supply,

Laser and camera control, as well as 5-step motor axes for a precise

3D measuring device

Our speciality: “Customised control systems

Are you developing a device and need a completely individual control system for it? That’s our speciality! For smaller quantities, this can be realised relatively quickly with the help of our standard controls, including a few purchased parts if necessary.

For larger quantities, a customised design is usually required. As a rule, the unit’s electronics should be combined on a single circuit board. This is more convenient, saves costs and brings advantages in wiring.

For example, you need power supplies, control panels, displays, inputs and outputs, sensor connections and perhaps also one or more motors in your device? We put these components on a PCB for you and follow your specifications (e.g. regarding environmental requirements and dimensions).

Step-by-step through all nessesary tests

The stepping motors and controllers can be customized individually.

For example:

- shaft

- flange

- coil

- connectin cable

- plugs

- environmental conditions

- interfaces

- programming

If our standard solutions do not lead directly to success, we offer the development of special hardware and software. In co-operation with you we provide a specification, which we realize normally at a fixed price.

We use the following technologies for you:

- Different simulators and emulators for the development of UP systems

- Development of digital (TTL/CMOS) and analogue circuits

- Programming of uP’s in Assembler, MicroPython and/or in various higher languages

- PC-programming in VB und C#

- Development of printed circuit boards by CAD

- GAL (Gate Array Logic), CPLD (Complex Programmable Logic Device), FPGA (Field Programmable Gate-Array)

- Automatic and semiautomatic measuring and inspection technology for electronics modules. Measuring technology for stepping motor drives (static and dynamic)

- Office applications for the documentation, calculation, presentation and administration

Other procedures and technologies (e.g. the EMC measuring technology) are available at our partner companies.

We support your work with the SmartStep-Family and PSC. Our telephone-hotline supports you with the integration of the drives. Click here for answers to fequently asked questions: FAQ